Lear Repair and Maintenance

SEAL Aviation is certified to repair Lear aircraft.

SEAL Aviation can perform NDT inspections on all Lear aircraft.

Common work scope performed by SEAL Aviation:

Integral fuel tank repair - Non Destructive Testing - Structural repair - 12 year prep of the center section and wing inspection - 12000 landing inspection center wing prep and wing inspection - 24 month internal wing inspections - Tip tank removal and installation along with end rib inspection - Wing extension removal - Fuel cell repair and replacement - Lear 55 fuel cell hangar relocation - Perform electrical bond check - Corrosion removal

Lear Fuel Tank Maintenance and Fuel Leak Repair

SEAL Aviation has extensive experience with 20, 30, 40, 50, 60 series aircraft along with the 20 series XR modification to the wing. By choosing the SEAL Aviation 'one-stop shop', you can rest easy knowing SEAL can complete any fuel leak repair while our NDT department seamlessly provides the inspections needed to ensure your aircraft is ready for flight.

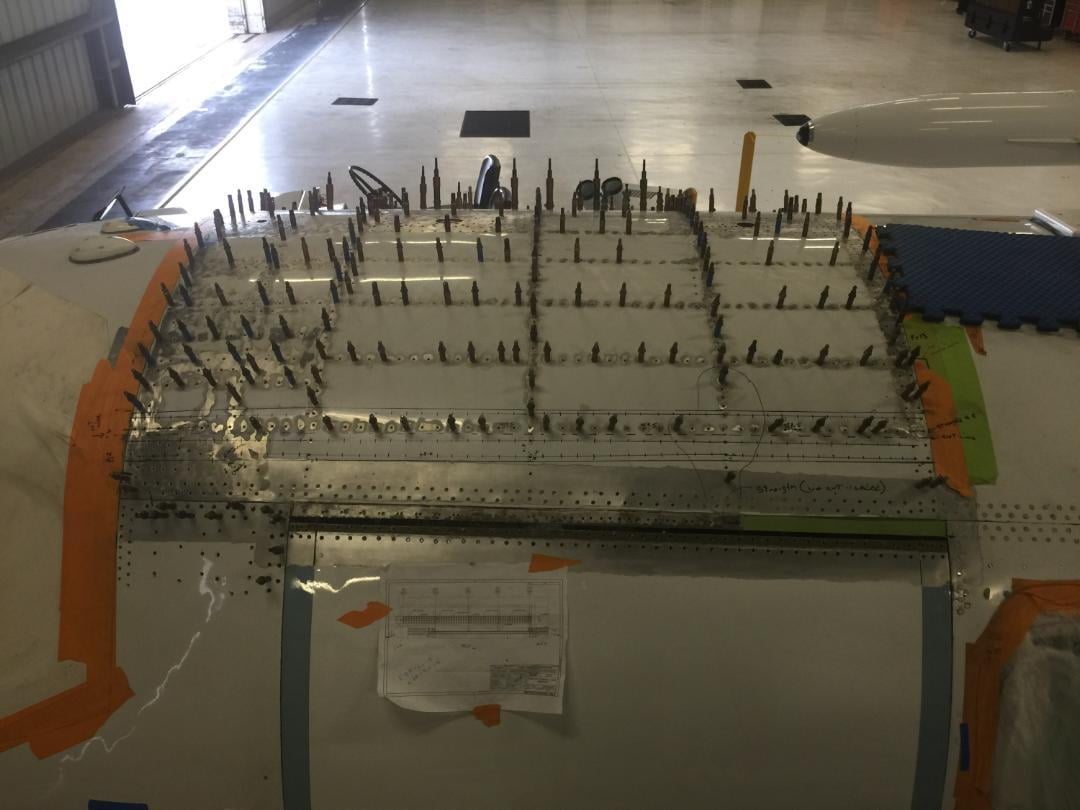

Lear Structural and Sheetmetal Repair

SEAL Aviation is an industry leader in heavy structural repairs on Lear and Bombardier aircraft. From wing inspections to stringer repairs to delta fin replacement, SEAL Aviation has the experience, tooling and parts available to the job right the first time. SEAL aviation is prepared to work with Bombardier engineering to ensure all repairs are completed to the manufacturer's specifications and in a timely matter.

Lear 60 Fuselage Repair

When your Lear needs the best team in the business, call SEAL Aviation. We are capable of performing repairs that are so complex and delicate, even aircraft manufacturers call SEAL to ensure the repair is done right the first time. We are fully capable of performing task (AD) 2017-11-09 Lear 60 Fuselage Repair. Call us today or request a quote right now!

Lear Wing Spar Inspection

SEAL Aviation can assist with Lear SB 45-57-13

If you need service bulletin SB 40-57-06, SB 45-57-13, SB 70-57-02, SB 75-57-01 complied with or if you find corrosion while performing any of these service bulletins, SEAL Aviation Combined Services can assist with removal of corrosion, NDT, flap peening/rotor peening, cold working of the fasteners and even replacement of the panels. SEAL Aviation has been an industry leader in Learjet maintenance and repairs for over a decade. Our team of experts has performed these tasks on many aircraft throughout the years and our Combined Services has optimized the process resulting in less down time for our customers.

SEAL Aviation is an industry leading FAA repair station

When it comes to critical repairs and structural maintenance, SEAL Aviation has the experience and techniques need to perform the job quickly and safely. We always strive to keeps costs down for our customers while ensuring the repair is completed correctly the first time. Critical repairs require a certain level of excellence that SEAL Aviation provides for every repair we perform. Only trust the best with your investment.