Relocation of Challenger Hydraulic System Requires Line Swaging

What Is Permaswaging©?

Permaswaging is a specialized technique that is used in the aviation industry that involves making permanent repairs to hydraulic, water and fuel lines. But what exactly is Permaswaging? Pronounced "swedge", Permaswaging is a cold-working technique that involves using specialized dies to form one piece of metal around another. In aviation, Permaswaging (sometimes referred to as swaging) is mostly used in fluid systems where a permanent joint with metal to metal sealing is required. Permaswaging results in a mechanical connection between the tubing and fitting that will act as a permanent container for fluid such as hydraulic fluid. Permaswaging aims to produce a uniform reduction of a tube to fitting connection to tolerances that would not require welding or other sealing.

Properly Permaswaging lines involves access to specialized tooling as well as years of practice to provide this service correctly. SEAL Aviation has invested in the required tool kits and has decades of aviation experience providing Permaswaging services for aircraft owners and operators. Combined with our mobile capabilities, this uniquely positions SEAL Aviation to be the best choice for relocating hydraulic or other Permaswaging needs. SEAL Aviation will come to your location, anywhere in the world, to perform this service on your aircraft.

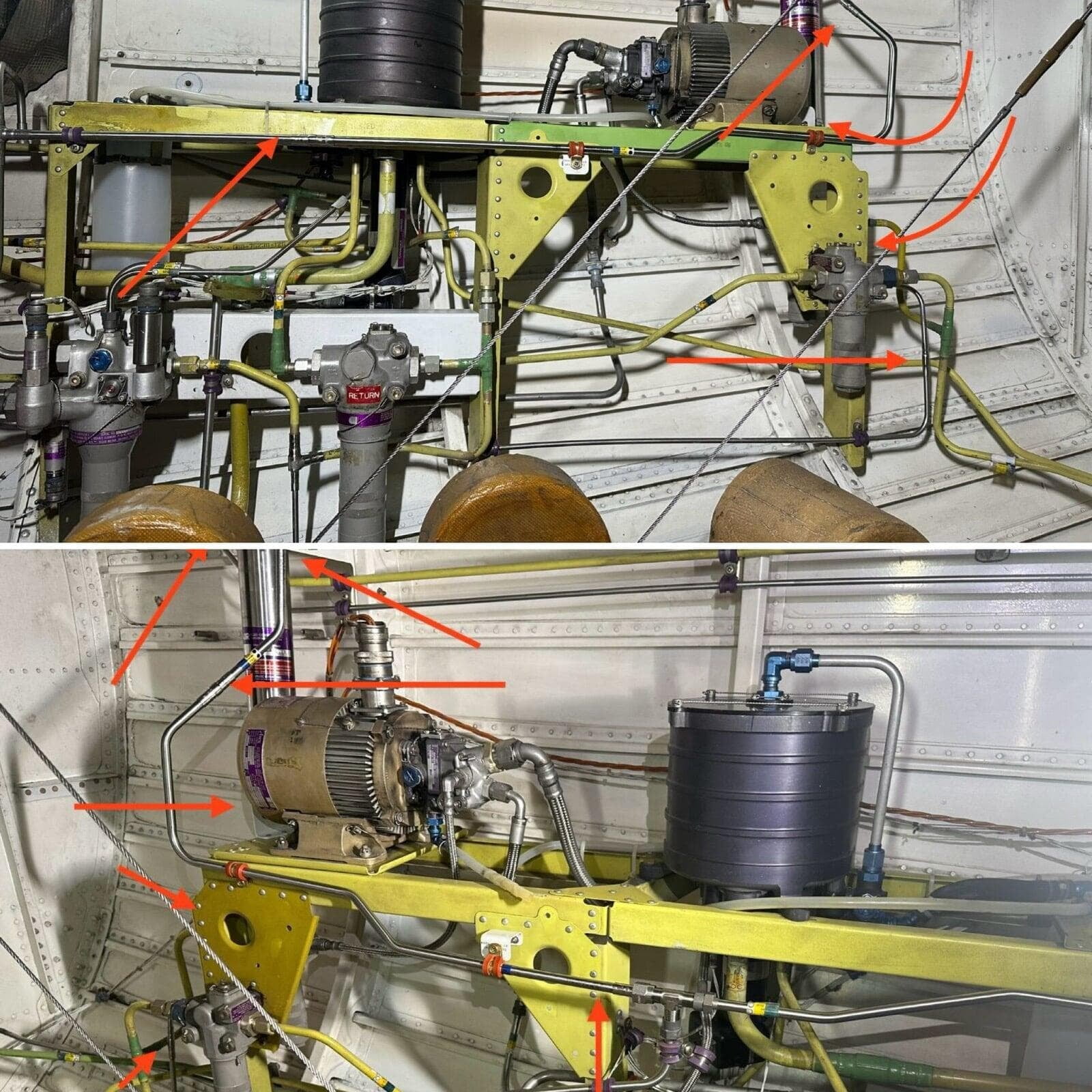

For a great example of how this flexibility benefits our customers, SEAL Aviation was called out to the customer's location in to assist the customer with Bombardier Service Bulletin 600-0764. This Service Bulletin details relocating the hydraulic system which requires swaging of new hydraulic lines. Bombardier has issued this AD to "address the failure of one of the brake accumulator screw caps/end caps, which could result in impact damage causing loss of both hydraulic systems No. 2 and No. 3, and the consequent loss of both braking and nose wheel steering, the potential for a runway excursion, and damage to the airplane." Having the tooling on-hand combined with our mobile capabilities made SEAL Aviation the perfect fit to assist with fabricating new hydraulic lines and relocating the hydraulic system. SEAL Aviation was successfully able to assist this AOG customer over the course of one weekend.

SEAL Aviation is a Part 145 repair station that operates a mobile company which has the capability to provide heavy structural repairs, fuel leak repairs, and non-destructive testing for your aircraft, anywhere in the world. SEAL Aviation is an FAA, EASA, Mexico authorized repair station and SEAL Aviation NDT Techs are SNT-TC-1A, NAS410, EASA and Cessna/Citation Certified. Click the button below to visit our website and request pricing.