If corrosion is not detected and treated in a timely manner, it can lead to costly repairs and downtime

Corrosion is one of the most common structural issues SEAL Aviation repairs on aircraft. Every aircraft eventually becomes vulnerable to the threat of metal corrosion. If corrosion is not detected and treated in a timely manner, it can lead to costly repairs and downtime. Ensuring your aircraft is regularly maintained and inspected by trained technicians can help mitigate the risk.

SEAL Aviation performs corrosion repairs on a Challenger CL-600-2B16 main entry door

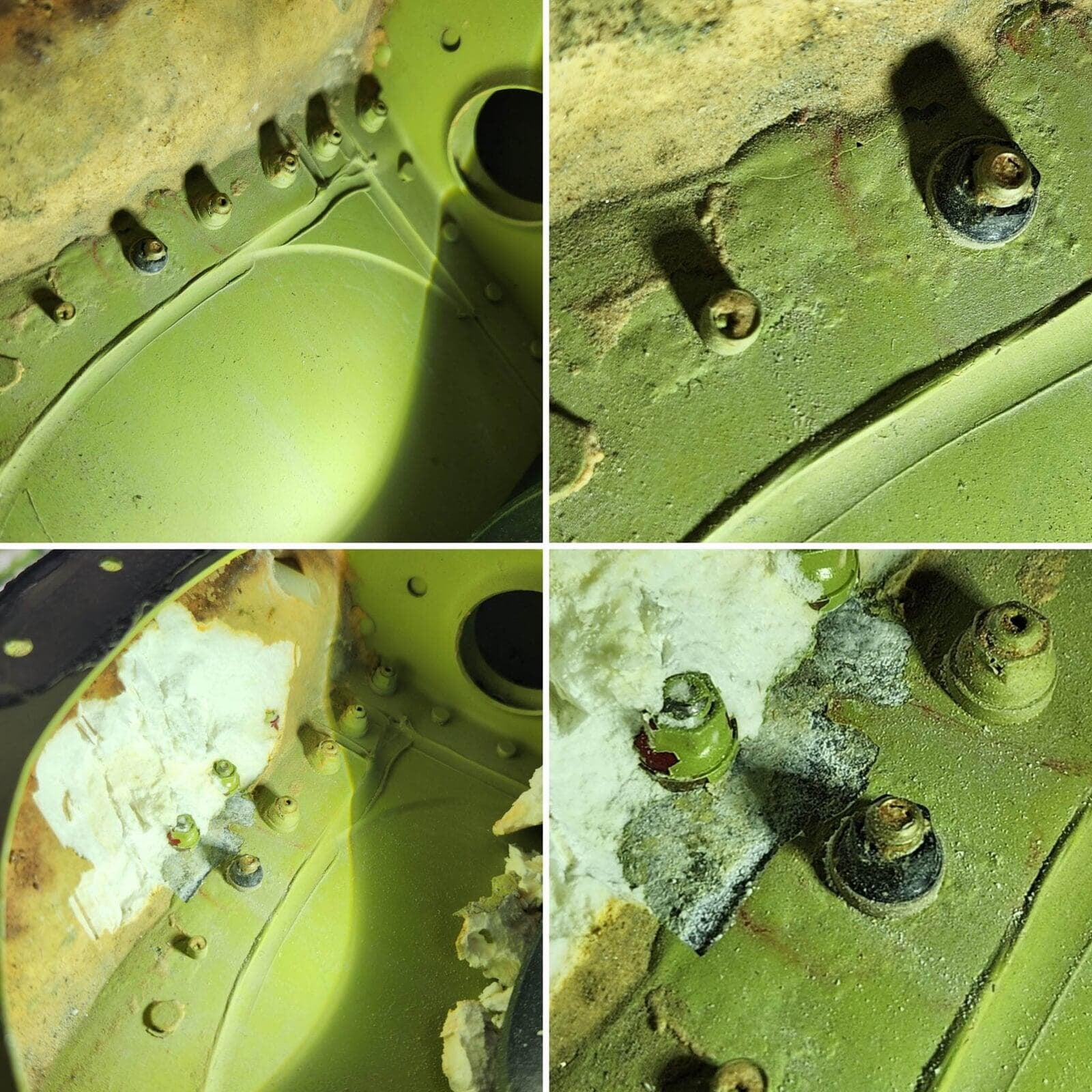

Bombardier has issued SB 604-52-007 for Challenger CL-600-2B16 models to address corrosion in the "lower structural elements of the passenger door". Bombardier states that purpose of this Service Bulletin, which effects serial numbers 5301 to 5665, is to remove the epoxy ramp and repair corrosion. The epoxy ramp around the MED, which has been found to deteriorate over time, can allow for moisture to enter which can lead to corrosion damage. Additional modifications include adding draining holes to allow access to facilitate scheduled inspections. On this particular door, corrosion was identified on the MED hinge, the forward and aft lower corners, the lower center channel and hinge fairings.

The epoxy ramp was removed as per the instructions to further assess the state of the corrosion damage and begin repairs. The deterioration of this epoxy is likely the source of the trapped moisture which contributed to the spread of the corrosion. Corrosion thrives under humid environments where deterioration of metal can occur relatively quickly. One of the best ways to prevent corrosion damage is to ensure the area in question is protected from moisture as much as possible. Sealant was added in select areas to further protect the area from moisture.

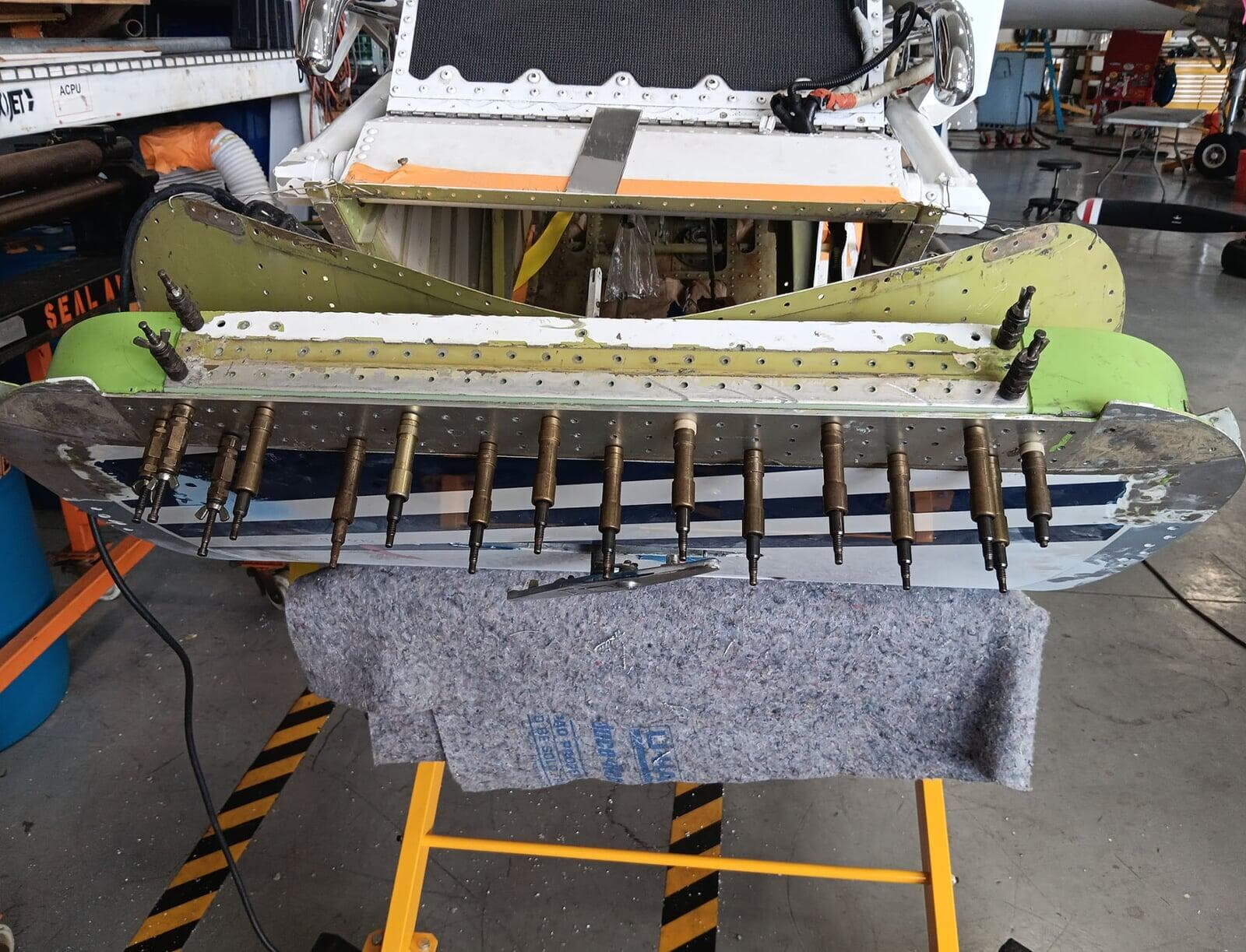

Corrosion was also identified on the forward and aft lower corners of the door. This section at the lowest part of the door is an area where moisture likely collected and became trapped. The pictures above indicate corrosion damage underneath the paint and around the fastener holes. The forward and aft lower corners of this door were removed and replaced as per the Service Bulletin.

The hinge was damaged beyond economic repair, requiring a new door hinge half to be machined as a replacement. The new hinge was match drilled to the exact specifications of the damaged hinge half. The other half of the hinge was salvaged and subsequently repaired by SEAL Aviation Structural Repair Technicians.

SEAL Aviation is an industry leader in aircraft structural repair

SEAL Aviation Structural Repair Technicians have decades of experience specializing in identifying and repairing corrosion. Our skilled technicians are trained to inspect for early signs of corrosion which can help prevent major maintenance events and down time. Key areas on a aircraft to inspect are fuel tanks, laboratory area, control hinges, battery boxes and anywhere on the aircraft that is devoid of paint. The best way to fight against costly corrosion repairs is early detection and removal.

Thankfully, there are many ways to fight against corrosion in the aviation industry. Having personnel maintain your aircraft that are trained to inspect for early signs of corrosion will help reduce down time and repair cost. Keeping an aircraft washed is imperative to prevent the accumulation of pollutants and dirt and can deter the progression of corrosion. Utilizing a corrosion inhibitor product can also play a role in preventing corrosion. Once identified, repairing corrosion damage is a job best left in the hands of highly trained and certified technicians who are familiar with all aircraft types.

SEAL Aviation is a Part 145 repair station that operates a mobile company which has the capability to provide heavy structural repairs, fuel leak repairs, and non-destructive testing for your aircraft, anywhere in the world. SEAL Aviation is an FAA, EASA, Mexico and Canada authorized repair station and SEAL Aviation NDT Techs are SNT-TC-1A, NAS410, EASA and Cessna/Citation NDT Certified.

Click or tap on the button below to request pricing.