SEAL Aviation NDT Non-Destructive Testing Services

SEAL Aviation can perform the following methods of Non-Destructive Testing:

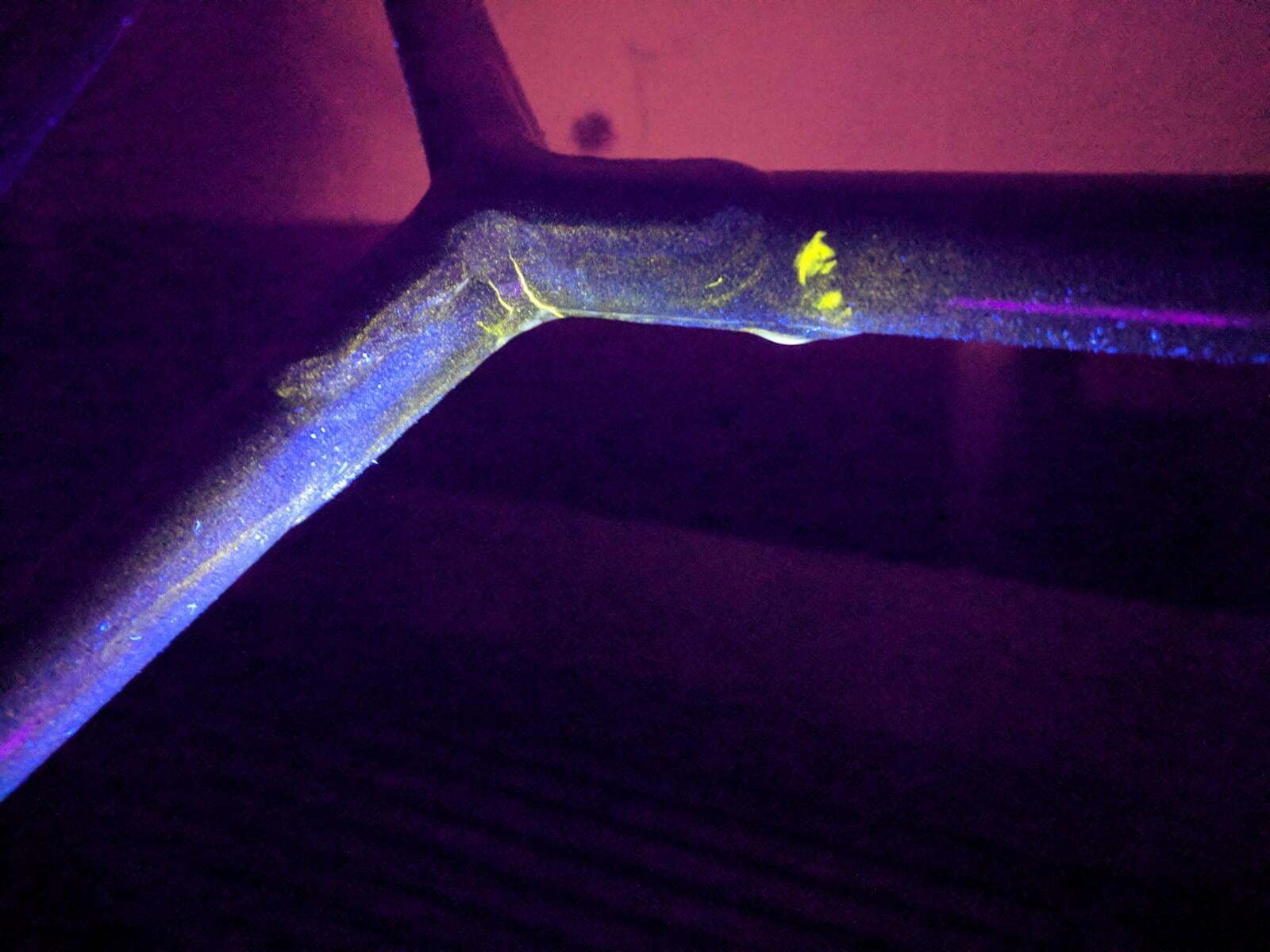

Radiography (RT) - Eddy Current (ET) - Ultrasound (UT) - Bond testing - Paint thickness testing - Liquid Penetrant (PT) - Magnetic Particle (MT) - Optical Prism

Tap or click on the service to learn more!

SEAL Aviation NDT technicians are ASNT SNT-TC-1A and NAS410 certified and SEAL Aviation is a Cessna Citation Certified Authorized Independent Facility.

SEAL Aviation has recognized the need to add mobile NDT as a service, allowing us to service your aircraft anywhere in the world. SEAL Aviation headquarters are located near the Ft. Lauderdale international airport in South Florida but we are uniquely equipped to bring our NDT testing to your location. SEAL Aviation personnel work together as a team to provide fast, economical aircraft inspections & NDT service without cutting any corners. Unlike other non-destructive testing companies, we specialize in aviation testing. We can service any aircraft, anywhere in the world.

What is Non-Destructive Testing?

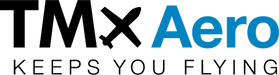

Non-Destructive Testing is a critical service offered by SEAL Aviation. NDT services allows our highly trained aircraft technicians the ability to perform a variety of tests on different parts of the aircraft without damaging it. The first step to any aircraft repair is a proper and thorough diagnosis. This must include an accurate assessment of the aircraft. All structural and critical components must pass rigorous testing. By integrating non-destructive testing in the process, the aircraft's internal makeup can be analyzed without invasive probing or removing the external panels.

Another great benefit to our NDT services is that they can be performed in less time than traditional testing. Often times, blindly searching for potential weak spots in trouble zones is time consuming and grounding an aircraft for extensive testing can be costly. To avoid this, NDT testing can discover defects in a timely fashion, allowing the aircraft to get back on the tarmac quickly and safely.

While the majority of NDT takes place on the aircraft frame, non-destructive testing is frequently used on aircraft landing gears, engines and other critical components. Because these pieces are composed of different materials, different methods of NDT must be performed. These include options like Radiography, Eddy Current, Ultrasound, Liquid Penetrant, Magnetic Particle, Bond Testing & Paint Thickness testing and optical prism. As a proud industry leader in NDT Services, providing non-destructive testing to our clients is just one of the ways we can provide you with the highest quality service. Nothing is more important than the integrity and safety of your aircraft. At SEAL Aviation, we hold your investment with the highest regard. We’ve staked our reputation and our name on the service we deliver our clients.

Call us today at

(954) 492-3522 Ext 3

SEAL Aviation has partnered with TMx Aero

Hydrostatic testing is a critical process for ensuring the structural integrity of aircraft pressure vessels, such as oxygen, fire prevention, and pneumatic cylinders. These vessels often operate under extreme pressure and can deteriorate over time, risking catastrophic failure that could endanger both aircraft and personnel. Experience the Best in Hydrostatic Testing Solutions with TMx Aero & SEAL Aviation!

SEAL AVIATION LEVEL III NDT SERVICES

SEAL Aviation is proud to offer contracted Level III services to help your business grow it's own NDT program. Our ASNT certified Level III can help your business set up a program to keep your testing in-house and ensure your program is adhering to FAA standards. SEAL Aviation's in-house Level III can work with your aspiring technicians to help train them with classroom hours and OJT to qualify them for the most popular aviation NDT disciplines. We also offer access to state of the art equipment and calibration services to ensure your technicians have the tools to confidently perform a quality inspection. We also provide staffing services for your current NDT program.

Call us today at (954) 492-3522 Ext 3 or email Sales@sealaviation.com to learn how Level III services can work for your business!